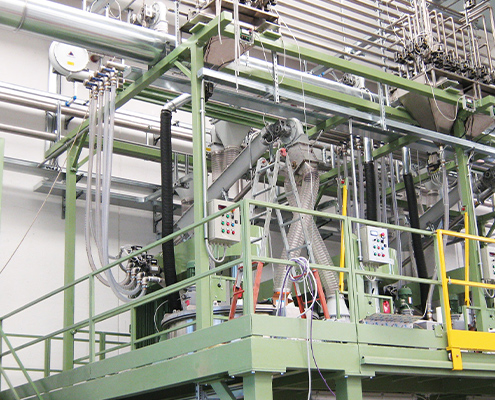

Idealtec conveyors, designed to transfer powders or granules from material collection and withdrawing points to product receiving machineries, offer design versatility and flexibility in easy to customize systems.

Our conveyor types range from drag conveying systems, with flexible transmission organs, mechanical conveyors, or with worm helix, screw conveyors, to suspension flow conveyors, transporting the material by means of flexible transmission organs, aeromechanical conveyors or in a fluid stream, pneumatic conveyors.

Selection and design criteria

Preliminary Analysis

The preliminary analysis, determining the choice of the conveyor type, takes into account:

1) The characterization of the material being handled, in particular:

- the physical properties (size, shape, density, surface area, temperature) and the interparticle forces (electrostatic, vdW, adhesive, aerodynamic) of the individual particles;

- the bulk properties (bulk density indexes and ratios, repose and friction angles, stresses and conditions of failure) of the collection of particles.

2) The evaluation of the operating and process conditions, in relation to:

- the required throughput;

- the entity of the material handling flows (number of stations, distances and differences in levels between the stations, complexity of the conveying path and flow directions);

- the material transfer frequency (continuous or discontinuous, constant or variable).

3) The analysis and determination of the environmental and operational conditions, regarding:

- available surface;

- adaptability to existing structures;

- scope for expansion;

- the presence of potentially explosive atmospheres.